Research and development

Research is the heart of our business

For close to 200 years, Höganäs Borgestad has pioneered the research and development of refractory materials. In order to be able to fulfil your current and future needs, we continuously develop new products and upgrade our existing solutions to incorporate new technical trends and safety requirements. We have a state-of-the-art laboratory at our production facility in Bjuv and our R&D team is composed of engineers and technicians with deep understanding of your operating practices. Using the latest technology and processing methods, they strive to develop the best materials for the most challenging applications. The latest addition to our extensive product portfolio is a new generation of monolithic products featuring even better properties than the current ones.

Comprehensive testing

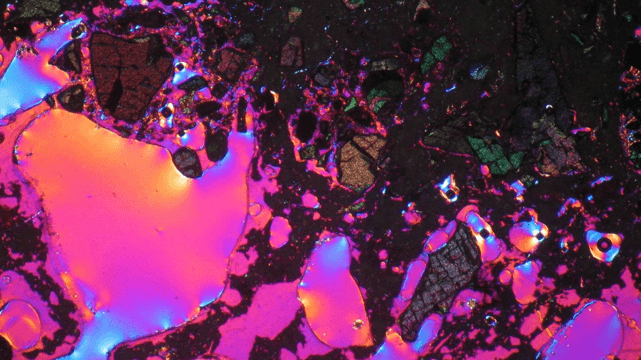

All our materials are subjected to comprehensive testing using the most sophisticated equipment. Among the tests we perform are:

- Bulk density and apparent porosity measures.

- Measurements of thermal conductivity to ensure our materials perform optimally in a given application.

- Refractoriness under Load (RUL) to identify deformation resistance under a defined load, temperature and time.

- Measurements of permeability to ascertain how well a refractory will stand up to slag, molten metal or gas penetration during service.

- Tests of abrasion resistance.

Through continuous sampling of all incoming raw materials, we maintain strict control over the quality of the product entering the Höganäs Borgestad production system.

Standard methods for testing of refractory bricks

Standard methods for testing of monolithic

Groundbreaking Innovations

Höganäs Borgestad has its roots in Höganäs Limited Company, founded in 1797.

The first production of refractory bricks started in Höganäs in 1825, and since 1876 the company has been located in Bjuv, in the southwestern part of Sweden.

Höganäs Borgestad is well known for high quality and continuous innovation. Through the years, we have added many features and new products to help you facilitate installation and achieve a longer lifetime for your refractories.

Some of the things we have introduced are:

- Organic fibers added to castables to achieve quick firing properties.

- Magnus high-performance magnesite bricks, designed to beat the toughest conditions.

- Silicon Carbide (SiC) castables to eliminate buildups.

- Glazed fireclay bricks to minimize buildups.

- The Anchorex anchoring system, to minimize time for molding.

- Coro Tex Pro corrosion protection of steel anchors and steel shells.

- Linometer XLNT to measure the remaining brick thickness in kiln linings.

- Interlocking, self-anchoring, cylindrical bricks for cyclones.

- High efficient counter-flow mixers.

- Firebolt® prefabricated block for bull nose and cooler roofs and walls.

- Lightweight, interlocking hanger roof for coolers.

- Development of No Cement Gel-bonded castables for Ferro-Alloy and Cement application. Initial trial has been planned in Norway.

- Pumpable and shot-creatable material has been developed and used in boilers application. A key product called HÖGANÄS PUMP LC 75 AR that displays both alkali and abrasion resistance has been tried successfully.

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Find us on social media