Höganäs Borgestad has entered into a contract for the supply of a full lime kiln for pulp and paper industry with diameter 3m and length 85.29m for Bukocel in Slovakia.

In cooperation with Clean Combustion which will supply the burner nozzle and Jammbco Industrial Solutions which will supply the new chain zone system, Höganäs Borgestad will manage the refractory system including design, engineering, supply of material and supervision. Installation is expected to start end of October 2019.

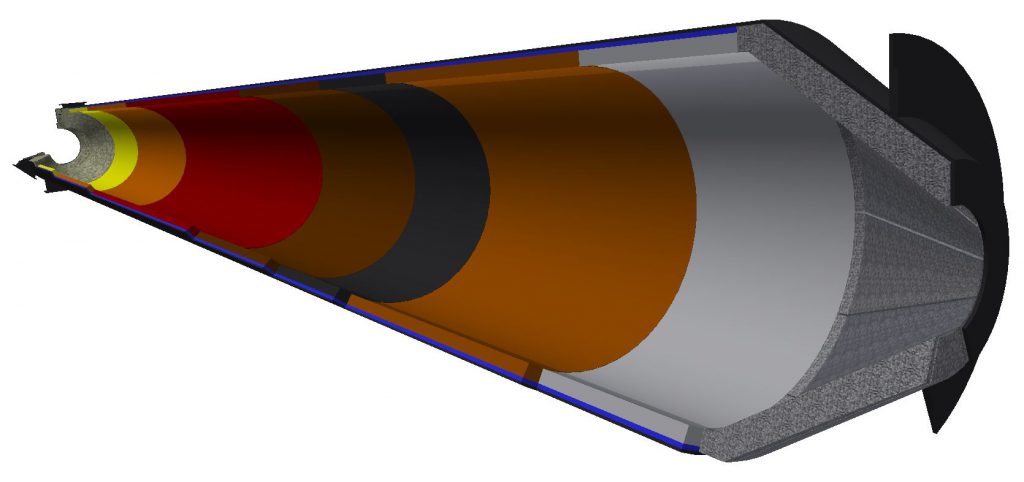

The refractory design was based on our energy saving solutions for rotary lime kilns for pulp and paper industry:

- Dam/Discharge zone (length: 1.25m): Höganäs Cast LC 50 AR, an alkali resistant low cement castable

- Burning zone (length: 27m): Silox 60, a high alumina brick based in mullite aggregate; together with the high insulation properties brick Höganäs Insul ME

- Intermediate/Drying zone (length 33m): Viking 330, an alkali resistant fireclay brick; together with the high insulation properties brick Höganäs Insul ME

We are confident that our energy saving design will provide a long term solution, as it reduces carbon footprint, prevents corrosion, reduces the steel shell temperature drastically leading to less mechanical problems, longer life time of the refractories while reducing fuel consumption.

To learn more about this project and our solutions for lime kilns, you may contact our sales representative, Mr. Mats-Ove Eriksson at mats.eriksson@hoganasborgestad.com or at +46(0)70 568 58 46.

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Find us on social media