Anchors

Give your refractories a proper foothold

Proper anchoring plays a decisive role in the performance and durability of the refractory lining.

The type of refractory brick or castable naturally determines the type of anchoring to be used. But other factors also affect choice: location, mobility, and chemical and thermal environment. Anchor positioning, size and quantity are important, too.

Our anchors are available in different grades of steel, to suit the prevailing chemical and thermal environment of the installation, as well as the steel quality of the shell.

Choose your electrodes carefully

A clean weld, with the correct welding electrode, is important. In choosing an electrode, two factors must be considered: the type of electrode dictated by the choice of anchor steel quality, which depends on prevailing thermal and chemical atmosphere, and then that is dictated by the steel quality of the casing and kiln shell.

When choosing the welding electrode, you must also consider the chemical and thermal environment of the installation, as well as the steel quality of the shell.

Please contact us for further information about what electrodes to use.

Steel Anchors

To make an optimum anchor choice, you must consider:

- Will the castable be poured or gunned?

- Is the location stationary (preheater, grate cooler, or ducting) or rotating (satelite or rotary cooler)?

- Will the castable be suspended (in an arch or hood)?

- What kind of chemical atmosphere will it be exposed to?

- Is insulation needed?

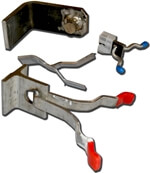

Types of anchors

Anchors come in a variety of shapes and cross-sections, to suit the needs of different types of installations.

Correct use is important

It is important to use the anchors correctly. You should consider the number of anchors to use, their distance from each other, and even their position relative to each other. Even their height within the castable lining is an important factor.

Anchorex boosts your efficiency

Traditional anchoring methods have many drawbacks – particularly the time and effort needed to install and ultimately wreck the castable lining.

Höganäs Borgestad understands this. That is why we perfected Anchorex. This comprehensive system not only provides optimal anchoring for all types of castables, but also effectively cuts time and labor for installation and wrecking in half, as well as increasing safety for installation personnel.

Anchoring bricks

Anchor brick frilagdSteel anchors for bricks come in two basic varieties: welded, and mechanically suspended. The former are used primarily for retaining brick walls, the latter primarily for suspended arches.

The same considerations concerning thermal and chemical atmosphere should be made when choosing anchors for bricks (and their welds, where applicable) as for castables.

The mechanical considerations are not complex, but it is important that they are correct.

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Find us on social media