KILN

Achieve world-class production capacity in your kiln

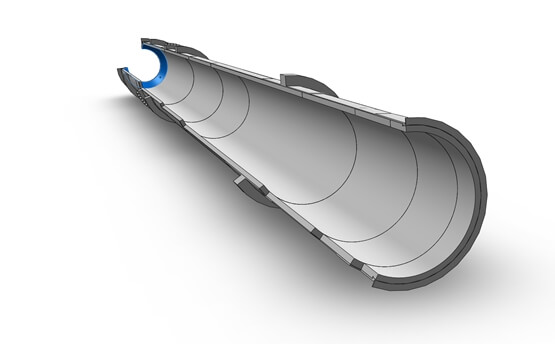

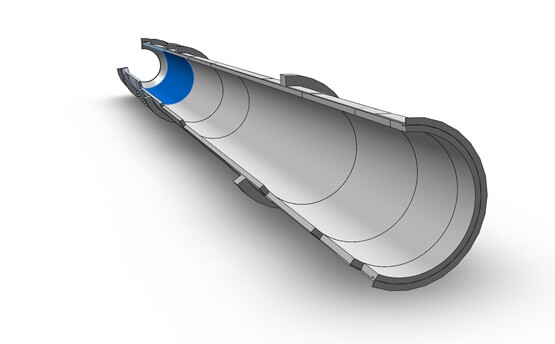

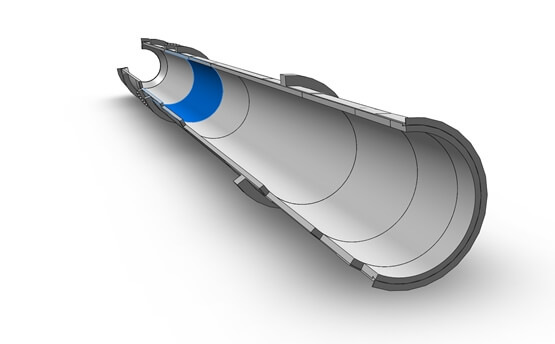

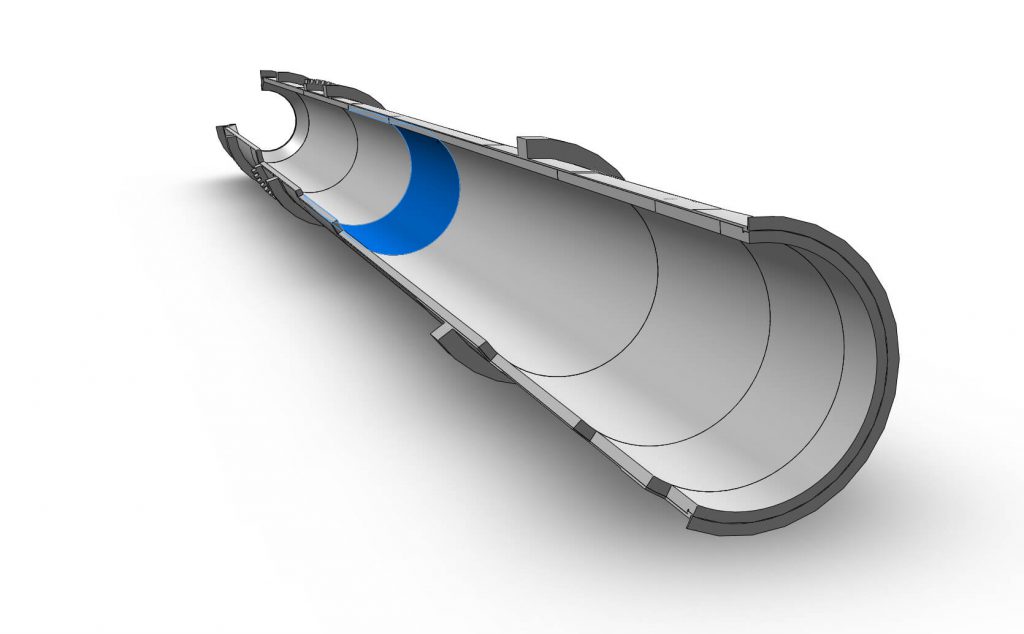

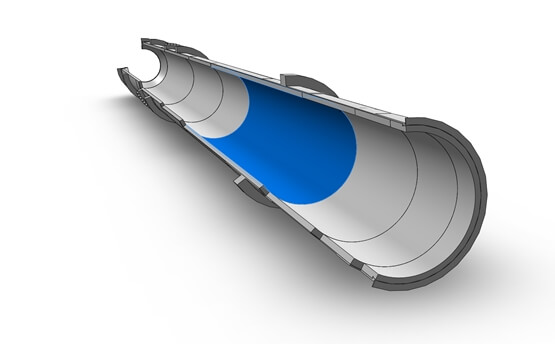

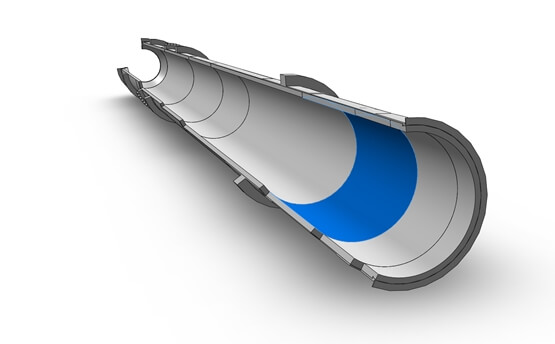

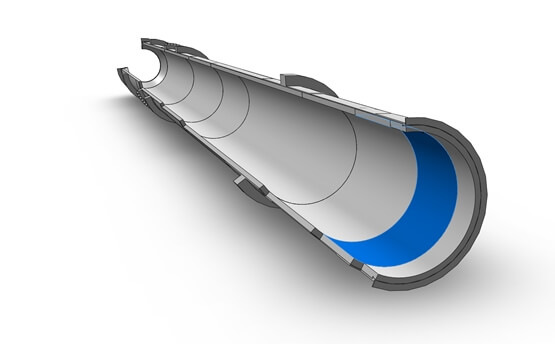

In this section we focus on dry-process kilns, as they represent the majority of kilns now in use. The refractory requirements of wet- and semi-dry process kilns are essentially similar after the inlet stage.

Today’s dry-process kilns are shorter, without loss of production capacity. Many producers use the kiln to burn waste materials – a good source of low-cost energy. Widespread use of alternative fuel can cause problems for the refractories that are installed in your kiln.

Inlet cone: The most important considerations in the inlet cone is alkali resistance. Raw meal can quickly deteriorate refractories that are not resistant, and temperature fluctuations can cause condensation of alkaline vapors in the refractory lining.

Inlet zone: The primary challenge for the lining in the inlet zone is alkali-resistance.

Safety zone: The primary criteria in the safety zone are alkali- and abrasion-resistance. Brick lining should have a progressively increasing refractoriness and alumina content

Upper transition zone: The correct magnesia-based refractories are needed due to the following variables:

- Variations in oxygen potential ,caused by use of multiple fuels. After several redox cycles, some brick qualities may become weak and friable.

- Operation with an unstable coating – caused by a variety of factors. Brick becomes exposed to infiltration by clinker liquid phase.

- Direct action of alkali chlorides and sulfates, a result of using several waste fuels. Brick may subsequently cap.

- Build-up of abnormal rings, resulting from unbalanced sulfate modulus.

- Kiln shell corrosion caused by sulfate and chloride diffusion through the refractory, can result from the burning of some waste fuels.

Burning zone: Combustion engineering and generation of clinker coating are the two factors paramount to the optimal functioning of the burning zone. Successful combustion engineering supports optimum clinker formation, and minimizes wear and stress on refractories and kiln shell. Poor combustion engineering leads to thermal overload and rapidly fluctuating redox conditions, which are bad for both refractory lining and clinker. Thermal overload will ultimately cause the refractory to melt. Redox conditions lead to the brick’s accelerated friability, or brittleness.

The second factor is equally important: the generation of clinker coating on the refractory brick. This protects the brick and helps the clinkerization reaction throughout the kiln.

Several variables can affect the maintenance of this coating including large fluctuations in raw meal parameters and poorly nodularised clinker can result in liquid phase segregation, the use of high-sulfur fuels, combined with poor combustion engineering and a number of factors that can cause coating to disappear completely.

Lower transition zone: Excessive ovality or damage, the kiln shell causes mechanical stress. This can lead to crushing and displacement of refractories and, ulitmately, may cause a catastrophic twisting of the brick lining. Use of alternative fuels with high alkaline and sulfur content may lead to “capping”, caused by the infiltration and condensation of alkalis in the brick. This phenomenon can also occur as a result of thermal overload, or from firing with the burner tip coincident with the nose ring or outlet zone. Thermal overload can also cause spalling, a result of thermal shock. Very abrasive “dusty” clinkers – high in SiO2 – can cause high abrasion wear on refractories.

Cooling zone: The discharge zone is often severely stressed. Abrasive clinker outfall can cause wear on both refractory linings and steel segments, and thermal shock and axial expansion often accelerate refractory wear. Therefore, brick linings should be made of flexible, highly abrasion-resistant brick.

Nose ring zone: When steel nose ring segments become worn out, producers have two alternatives: to replace them and reline with brick, or keep them and switch to a castable lining.

Höganäs Borgestad can offer you the right refractory solutions for your kiln lining, which are listed on the table below:

| Area / Temperature (°C) | Processing Conditions | Brick solution Standard Conditions | Brick solutions Severe Conditions | Monolithics solution | Energy Savings Brick solutions |

|---|---|---|---|---|---|

| Inlet cone 850 (°C) | Alkali attack | Viking 330 Mortar HÖGANÄS H-15 | Viking 330 Mortar HÖGANÄS H-15 | Standard Conditions HÖGANÄS CAST LC 50AR HÖGANÄS CAST LC 75AR Severe Conditions HÖGANÄS CAST CC S10 CoroTex Pro | HÖGANÄS CAST LC 50AR (Precasted blocks) |

| Inlet zone 850-1000 (°C) | Alkali attack | Viking 330 Mortar HÖGANÄS H-15 | Alex Viking 450 Alsic 500 Mortar HÖGANÄS H-15 CoroTex Pro | Viking 330 Viking 450 Insulation HÖGANÄS INSUL ME Mortar HÖGANÄS H-15 CoroTex Pro or acid primer |

|

| Safety zone ≥1200(°C) | Abrasion Alkali attack Thermal overload | Victor 60,70,80RK Alex Mortar HÖGANÄS T | Victor 60,70,80RK Alex Mortar HÖGANÄS T CoroTex Pro | Viking 330 Viking 450 Alex Alsic 500 Silox 60 Insulation HÖGANÄS INSUL ME Mortar HÖGANÄS H-15 HÖGANÄS T CoroTex Pro or acid primer |

|

| Upper Transition zone 1300-1600(°C) | Redox cycles Infiltration by clinker liquid phase Alkali attack Ring formation Build ups | Magnus CF02 Mortar Magnus Bond | Magnus 87 AF Magnus 90 AF Mortar Magnus Bond | Magnus 87 AF Insulation HÖGANÄS INSUL SX Mortar Magnus Bond CoroTex Pro |

|

| Burning zone 1400-1600(°C) | Thermal overload Redox conditions Liquid phase segregation Ring formation Build ups | Magnus CF02 Mortar Magnus Bond | Magnus 87 AF Magnus 90 AF Mortar Magnus Bond | Magnus 87 AF Insulation HÖGANÄS INSUL SX Mortar Magnus Bond CoroTex Pro |

|

| Lower transition zone 1300-1600(°C) | Alkali attack Thermal overload Abrasive dusty clinkers Ring formation Build ups | Magnus 87 AF Mortar Magnus Bond | Magnus 87 AF Magnus 90 AF Mortar Magnus Bond | Magnus 87 AF Insulation HÖGANÄS INSUL SX Mortar Magnus Bond CoroTex Pro |

|

| Cooling zone | Abrasion Thermal shock Axial expansion | Victor60, 70, 80RK Mortar HÖGANÄS T | Alsic 500(no liquid phase is allowed to touch it) Mortar HÖGANÄS T | Standard Conditions HÖGANÄS CAST LC 801 Severe Conditions HÖGANÄS GUN CC S101 CoroTex Pro Stainless steel anchors | Victor 60,70,80RK Alsic 500 Silox 60 Insulation HÖGANÄS INSUL ME Mortar HÖGANÄS H-15 HÖGANÄS T CoroTex Pro |

| Nosering zone 1400-1600(°C) | Abrasion Thermal shock Axial expansion | Victor60, 70, 80RK Mortar HÖGANÄS T | Alsic 500 Mortar HÖGANÄS T | Standard Conditions HÖGANÄS CAST LC 75 AR HÖGANÄS CAST LC S30 Severe Conditions HÖGANÄS GUN CC S101 CoroTex Pro Stainless steel anchors | HÖGANÄS CAST CC S10 (Precasted blocks) |

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Find us on social media