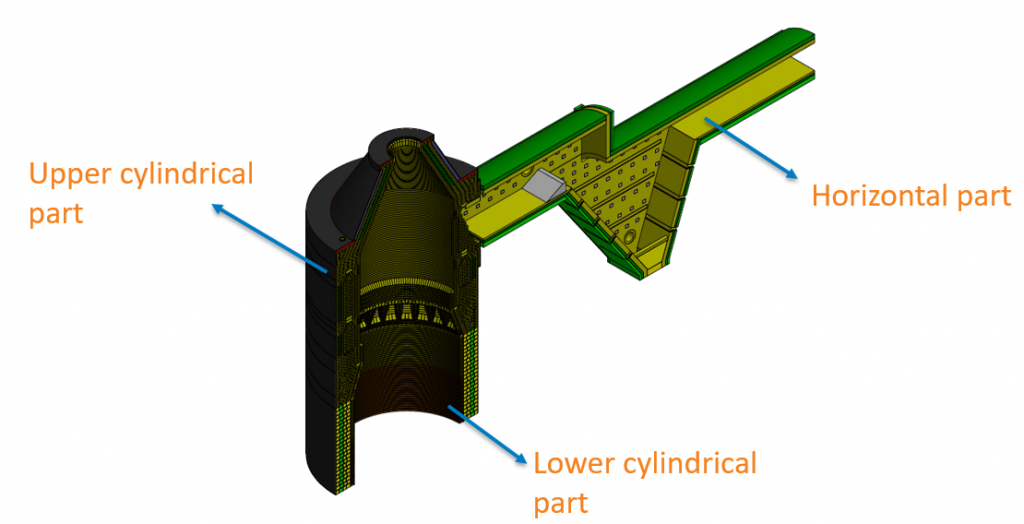

Coke Oven, Dry Quenching Chamber / Waste Gas channel

This is an energy saving system in which, during quenching process, sensible heat of the red hot coke is recovered and utilized for power generation or as steam.

Coke dry quenching appears as the most valid system to reduce air pollution allowing at the same time a remarkable energy recovery or saving, especially when it is associated with coal preheating. In addition, dry quenched coke is harder and stronger, and its moisture content is much lower than that of wet quenched coke.

Coke dry quenching can be applied in principle at new and existing iron and steel plants. Coke dry quenching systems have been installed in many steel works and coke ovens.

Click to enlarge

For more information about our refractory solutions for steel industry, please contact us.

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Find us on social media