Foundry ladles

Ladles are used in foundryindustry to transfer molten metal from one location to another, generally from a melting furnace to a holding furnace. They are often used to hold metal while it is treated by degassing and/or fluxing. They are filled by tapping out a furnace or utilizing a metal transfer pump. Most transfer ladles require supporting steel shells and are lined with refractory, which can be a precast shape or cast in place. Due to extreme conditions in which the refractory is subjected, it must be resistant to thermal shock, cracks and erosion.

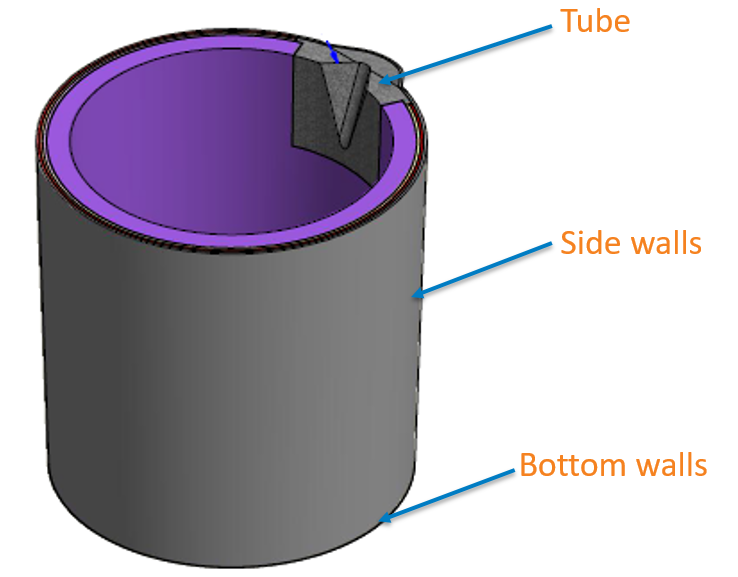

Click to enlarge

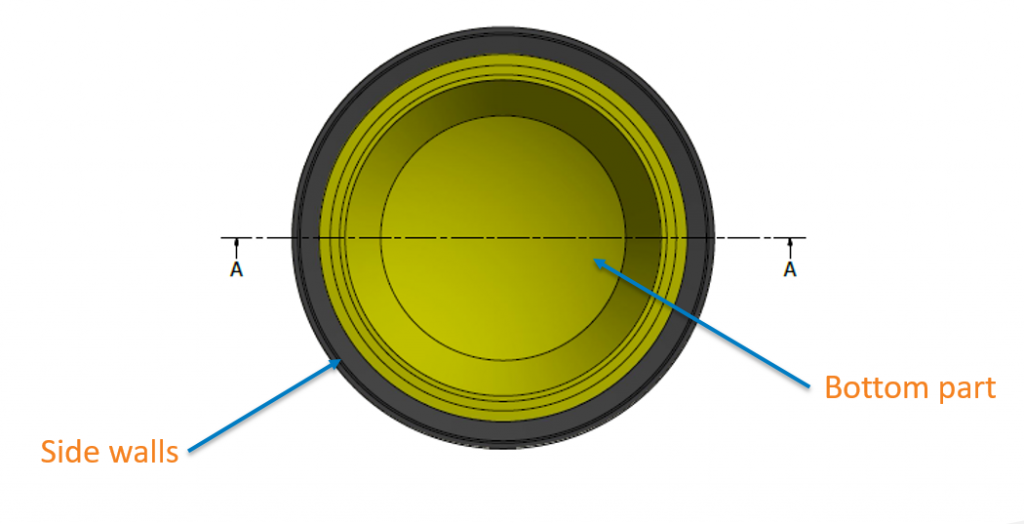

Click to enlarge

For more information about our refractory solutions for steel industry, please contact us.

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Find us on social media