Lead pot

Modern steelworks involve the three production stages: steelmaking, refining, and continuous casting. In steelmaking–continuous casting, a ladle corresponds to the furnace (smelting molten steel converter) used in container production.

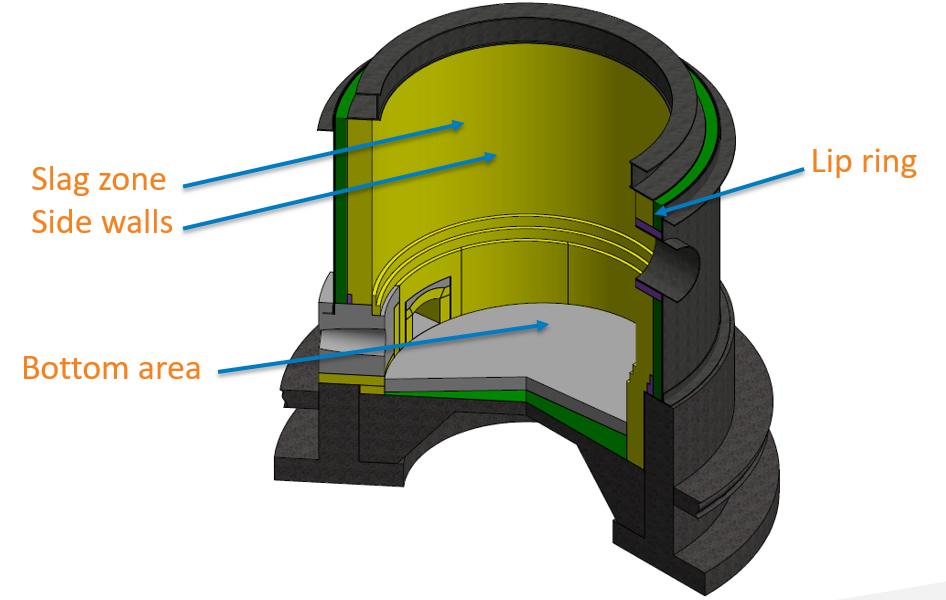

Ladles are generally cylindrical, with an open top, and a small offcentre casting nozzle in the base. They consist of an external steel shell (50-100 rnrn thick), and several layers of internal refractory lining (up to 400 mm). A refractory-lined steel lid can be used to cover the top of the ladle.

Under normal operating conditions, a vertical temperature gradient forms in the ladle. This thermal stratification is undesirable. It generally causes variations in casting temperature (degrading caster performance).

Click to enlarge

For more information about our refractory solutions for steel industry, please contact us.

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Find us on social media