Tundish

In the process of continuous casting, to transfer liquid steel from a steel teeming ladle to the mould, an intermediate vessel, called a tundish, is used. A tundishis a rectangular big end up refractory lined open container which may have a refractory lined cover on the top. The tundish bottom has one or more holes with slide gate(s) or stopper rod(s) for controlling the metal flow. It is used to feed liquid steel into the copper moulds of a continuous casting machine, so as to avoid splashing and give a smoother flow.

Due to the process layout, tundish refractory linings are designed to withstand thermal shock, prevent thermal loss, prevent oxidation, and resist erosion and corrosion.

Click to enlarge

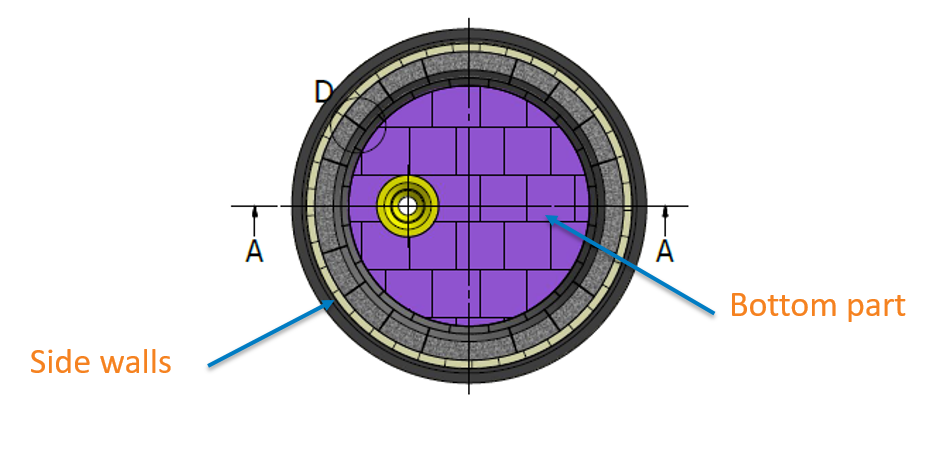

Tundish can also be lined with Firebolts (refractory precasts) as shown in the model below.

Click to enlarge

For more information about our refractory solutions for steel industry, please contact us.

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Find us on social media