Casthouse

Unique refractories for unique furnaces!

Almost all casthouse, melting and holding furnaces have one thing in common — each one is unique! That’s why we have developed a comprehensive range of refractory solutions to improve the performance of your unique production.

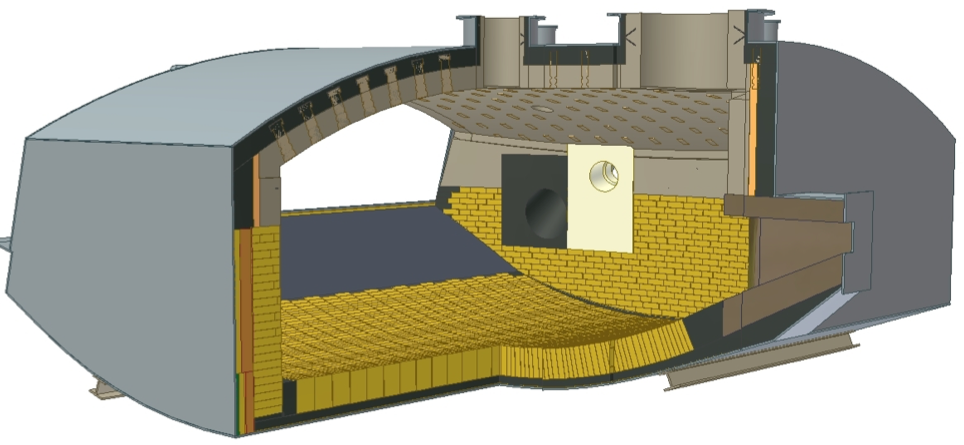

In furnace linings, the focus is to maintain a stable heat balance throughout the furnace’s lifetime, and keep the isotherm for the freezing point of the metal within the hot face lining to minimize the risk of a breakout of molten metal. We offer a number of flexible, proven solutions — based on bricks, monolithics and prefabricated shapes — that will help you to do this.

Designing the lining is an also a matter of finding the right balance between output volume and the lining’s functional lifetime, the thicker the brick, or castable lining, the longer its life. In addition, identifying the right amount of insulation is an important factor in getting the best solution.

The extreme environment of the holding furnace makes renovation an ongoing process, regardless of the quality of the refractories and their installation. Höganäs Borgestad offers a full maintenance support.

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Get installation instructions direct in your mobile phone, together with product and safety data for all Höganäs Borgestad monolithic products

Find us on social media